Q&A with the CEO: Why was Santos® created?

In this month’s Q&A, Steve Beck, CEO of SantosHuman Inc., addresses the question of why Santos was created.

Q: Why was Santos® created?

Santos® exists because Trial & Error is a terrible approach to design.

To unpack this a bit and make sure we’re all thinking about the same thing, let’s look at how Trial & Error is used in a cottage industry. Our example begins with an artisan, alone in a workshop, diligently giving physical form to some radical new wooden chair design. It’s complex enough to require several weeks to complete but as soon as the glue dries, our artisan sits down to reflect on a job well done. This is the Trial part in the scenario and while the chair’s aesthetics are impressive, it falls apart almost immediately. And that’s the Error part. Having completed the 1st Trial & Error iteration, the artisan must now work to address the flaws in the design through a series of subsequent iterations.

To unpack this a bit and make sure we’re all thinking about the same thing, let’s look at how Trial & Error is used in a cottage industry. Our example begins with an artisan, alone in a workshop, diligently giving physical form to some radical new wooden chair design. It’s complex enough to require several weeks to complete but as soon as the glue dries, our artisan sits down to reflect on a job well done. This is the Trial part in the scenario and while the chair’s aesthetics are impressive, it falls apart almost immediately. And that’s the Error part. Having completed the 1st Trial & Error iteration, the artisan must now work to address the flaws in the design through a series of subsequent iterations.

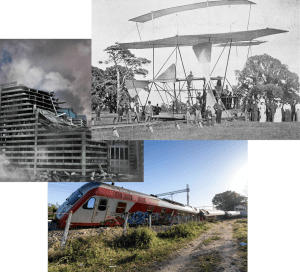

For products where materials are cheap, production is simple, and function is not critical, design by Trial & Error is often the only viable option. But imagine using that approach to design a high-rise apartment building where structural integrity could not be determined until full occupancy on a windy day. Or, to design an aircraft where aerodynamic properties could not be determined until after take-off. Or, to design a high-speed passenger train where nobody knows if the suspension systems will withstand the forces involved in a fast, twisty trip through a mountain range.

Trial & Error in these cases would be unthinkable. Further, it would be impossible to have ever developed today’s exceptionally high-quality products with their amazing capabilities using Trial & Error. Yet, products with amazing capabilities do exist, and they are of exceptionally high quality, so how is this accomplished?

Predictive Models for Virtual Testing

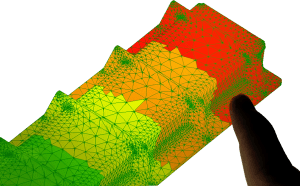

The quality and capabilities available in products today are achieved through the use of mathematical models that can virtually test properties critical to the design including structural integrity, aerodynamics, and how well mechanical systems perform during operation.

How does that work?

Let’s continue with our chair design example, but instead of expending the time and materials required to test and refine a series of complete chairs, a mathematical model is used to predict structural integrity for a virtual version of the chair, relative to a range of occupant weights. Upon completion, the virtual tests provide insight as to where the chair’s structure is sound versus where it may fail. Armed with this insight, our artisan modifies the virtual chair design to address the weak areas, runs additional virtual tests to confirm the solution, and then moves quickly into production without ever having to create a single physical prototype.

Let’s continue with our chair design example, but instead of expending the time and materials required to test and refine a series of complete chairs, a mathematical model is used to predict structural integrity for a virtual version of the chair, relative to a range of occupant weights. Upon completion, the virtual tests provide insight as to where the chair’s structure is sound versus where it may fail. Armed with this insight, our artisan modifies the virtual chair design to address the weak areas, runs additional virtual tests to confirm the solution, and then moves quickly into production without ever having to create a single physical prototype.

While obviously a superior approach to guessing and hoping for the best (a.k.a. Trial & Error), the above scenario is not likely to fit within a cottage industry business model. The cost of the technology required to use predictive models as described would be far beyond the means of a typical artisan. But for products where materials are expensive, production is complicated, and function is critical, Trial & Error is avoided wherever predictive models exist. Why? Because predictive models provide critical insight early in a product’s design cycle. And why is that important?

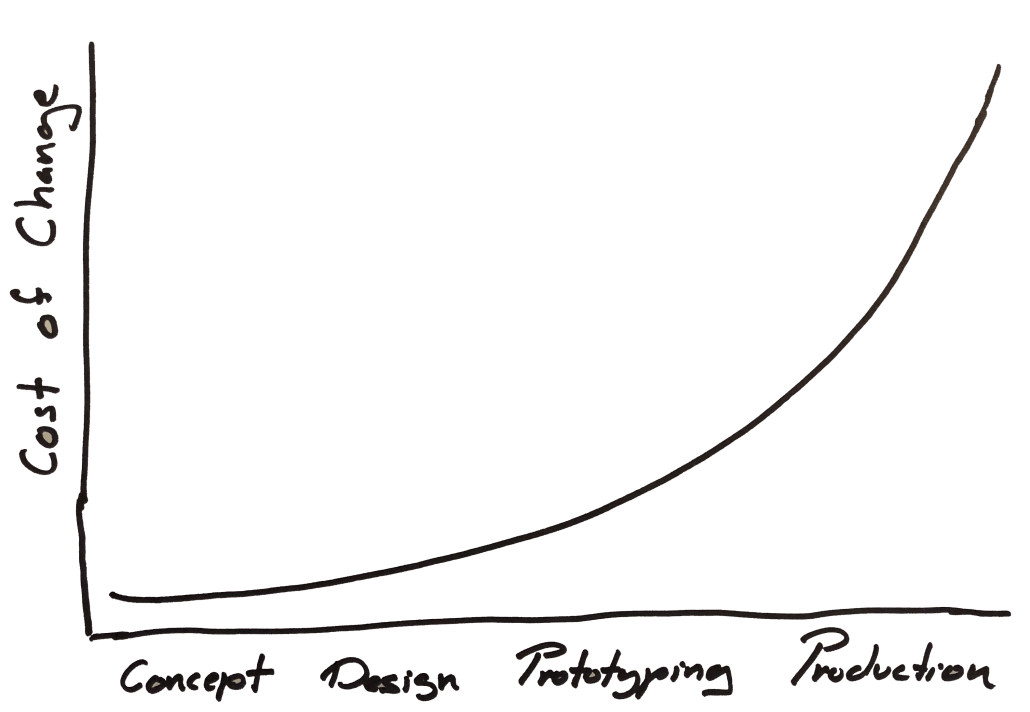

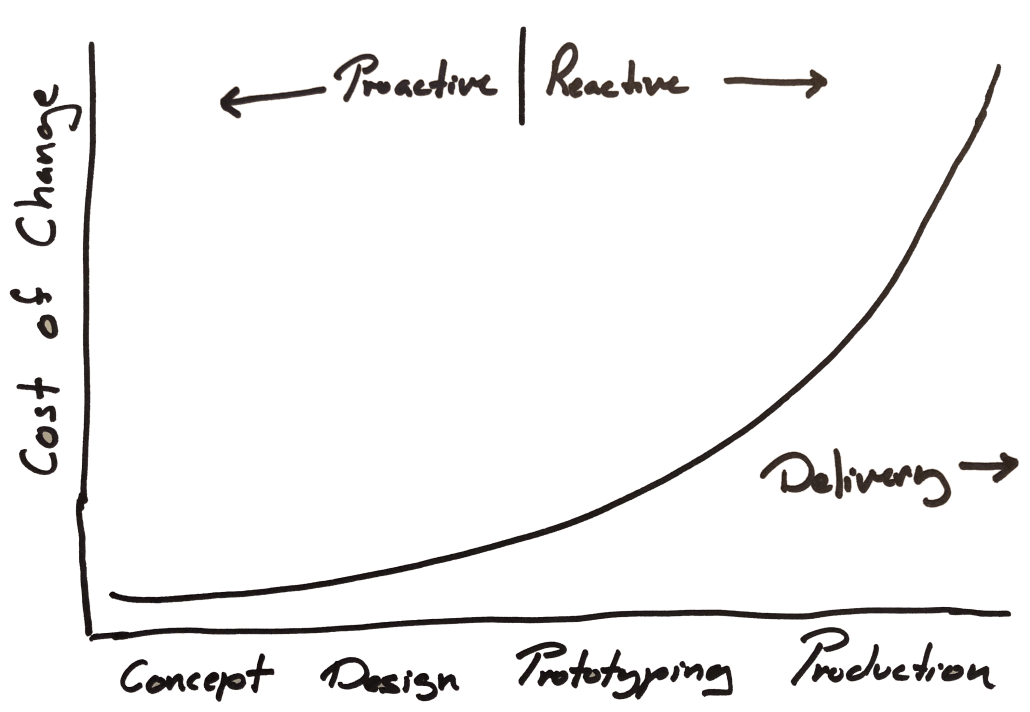

The ability to gain insight early in a design cycle is important because the earlier the need for change is detected, the less costly those changes are to make. And it’s not just a little bit cheaper. This is a well-studied relationship where change becomes significantly more expensive the closer a product gets to production. Post-production, the cost of change can be staggering.

This is why predictive models are so valuable and have been so widely adopted. Predictive models provide critical insight at the earliest stages of design, leading to better designs that can be brought into production sooner, which significantly benefits the bottom line of nearly every company, in every industry.

What does this have to do with Santos?

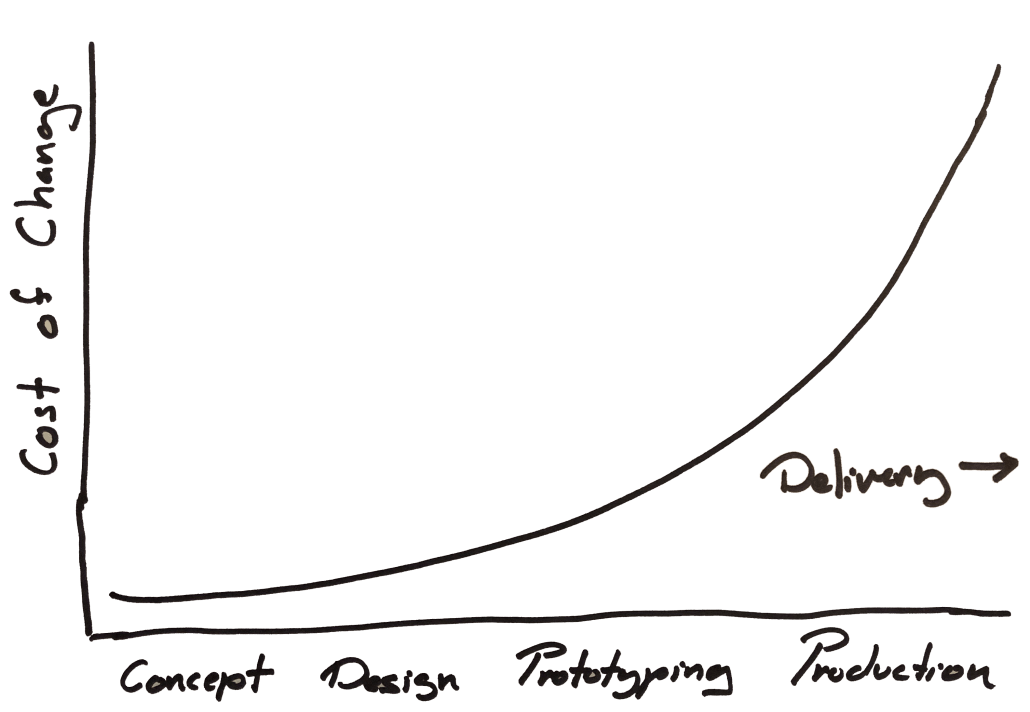

As valuable as these widely adopted models are, none of them have the ability to predict whether humans can interact with products or processes effectively and safely. And, because there has never been a way to predict the Human-in-the-Loop, all industries have had to rely on Trial & Error for human-centric design. One of the many unfortunate results of this is that the United States Department of Defense (US DoD) is often required to address usability issues after systems have already been delivered; when options to address design issues are most limited and also most expensive to implement.

Santos: The Alternative to Trial & Error

With all of that in mind, let’s return to the question. Why was Santos® created?

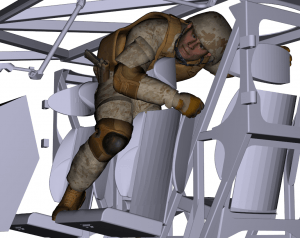

Santos was created to eliminate Trial & Error from human-centric design. The genesis story begins in the early 2000’s when the Tank Automotive Command Center (TACOM) was considering the development of the next generation tank. History suggested it could take as long as 13 years for a new tank design to evolve from whitepaper to production. Over those 13 years, 9 physical prototypes could be required at an estimated cost of $1B (USD) each. One of the primary reasons $9B worth of physical prototypes could be required would be to ensure critical Warfighter-in-the-Loop issues are understood and addressed because failure to do so will cost lives.

TACOM understood it was relying on the same Trial & Error approach to design that an artisan chair maker uses. But instead of evaluating a wooden chair, Trial & Error would be used to develop and refine an entire tank in order to make sure warfighters are able to operate its sophisticated systems safely and effectively. Each iteration was going to cost US Taxpayers $1B and TACOM wanted a more objective and cost-effective approach. They wanted to virtually test for Warfighter-centric issues in the same way that Finite Element Analysis (FEA) is used to virtually test for structural integrity issues, or the way Computational Fluid Dynamics (CFD) is used to virtually test for aerodynamic issues, or the way Multi-Body Dynamics (MBD) is used to virtually test for mechanical system operation issues. Those predictive models significantly reduce the need for physical prototypes. TACOM wanted to do the same thing for Warfighter-centric design.

That’s the problem we were asked to solve in 2003.

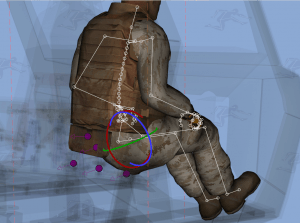

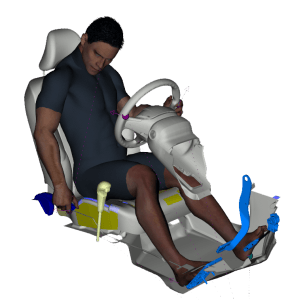

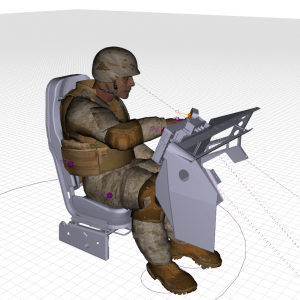

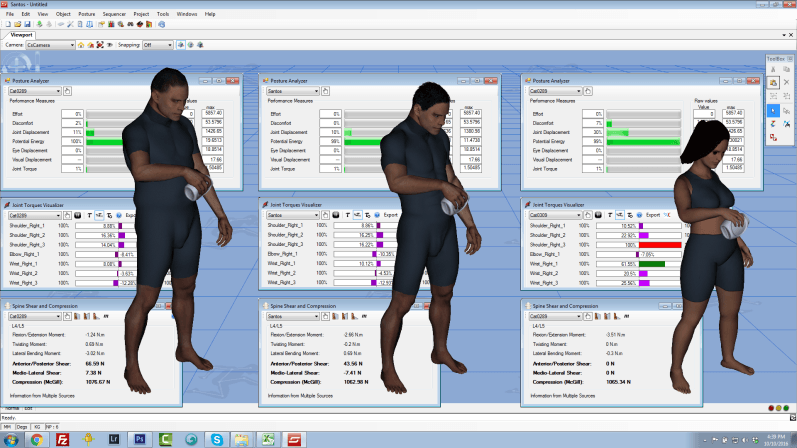

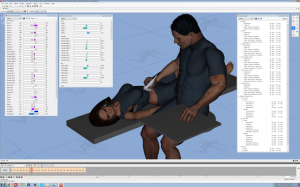

And we did it. We solved the problem. The research conducted in pursuit of this solution resulted in what is now commonly referred to as Santos®. Santos technologies include the ability to predict human physical behavior and performance so that Warfighter-in-the-Loop issues can be identified and addressed at the earliest stages of design. Now, instead of expending massive resources at the end of a design cycle to test system usability in a reactive role when options for change are most limited and most expensive, Santos® allows design teams to perform Warfighter-centric system evaluations in a proactive role, at the earliest stages of design. This can only be done with a predictive human model.

Santos® Means No More Trial & Error in Human-Centric Design

If you’re interested in seeing a quick example deployment of this technology, click on the image below to go directly to a previously posted blog that includes a video demonstration. Or, feel free to contact us directly at Sales@SantosHumanInc.com.

Thanks for tuning in and, as always, let us know what you think. We’d love to hear from you.

Cheers,

– S

Their initial assumption had been that an existing commercial, off-the-shelf

Their initial assumption had been that an existing commercial, off-the-shelf

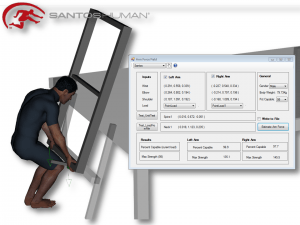

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury.

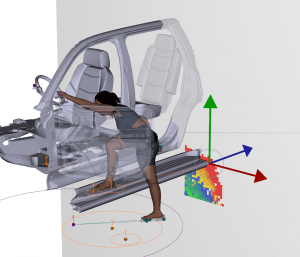

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury. In this first addendum entry, a global manufacturer in a highly competitive industry redesigned the thumb-operated switchgear on a new product scheduled to be in production soon. They told us their usual approach to evaluating something like this requires a working physical prototype and can take between two and three months to complete. Early on they were notified that a prototype would not be available prior to production so their plan had been to perform the study as soon as the vehicle was in production. The problem was that the company expected to be producing thousands of these vehicles every day when launched.

In this first addendum entry, a global manufacturer in a highly competitive industry redesigned the thumb-operated switchgear on a new product scheduled to be in production soon. They told us their usual approach to evaluating something like this requires a working physical prototype and can take between two and three months to complete. Early on they were notified that a prototype would not be available prior to production so their plan had been to perform the study as soon as the vehicle was in production. The problem was that the company expected to be producing thousands of these vehicles every day when launched. They contacted us hoping there might be some way to use just the CAD geometry to perform the switchgear usability evaluations prior to launch.

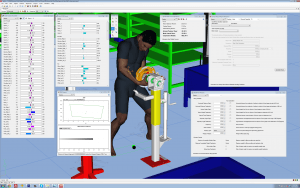

They contacted us hoping there might be some way to use just the CAD geometry to perform the switchgear usability evaluations prior to launch. Designing for Humans Earlier in the Process. The Santos first-principles approach to predicting physical human behavior and performance allows human-in-the-loop criteria to be considered at the earliest stages of product development. This enables our defense and private industry clients to design for increased performance and increased customer satisfaction from the start resulting in

Designing for Humans Earlier in the Process. The Santos first-principles approach to predicting physical human behavior and performance allows human-in-the-loop criteria to be considered at the earliest stages of product development. This enables our defense and private industry clients to design for increased performance and increased customer satisfaction from the start resulting in

A: The research that led to the human simulation capabilities now commonly referred to as Santos® was originally funded by the United States Army Tank-Automotive and Armaments Command (

A: The research that led to the human simulation capabilities now commonly referred to as Santos® was originally funded by the United States Army Tank-Automotive and Armaments Command ( TACOM program managers also relayed that one of the primary reasons for creating these prototypes was to ensure that warfighter-in-the-loop issues were identified and addressed prior to production because failure to do so will cost lives. The ability to assess these types of issues virtually and reduce the number of physical prototypes required represented a significant opportunity to reduce expenditures.

TACOM program managers also relayed that one of the primary reasons for creating these prototypes was to ensure that warfighter-in-the-loop issues were identified and addressed prior to production because failure to do so will cost lives. The ability to assess these types of issues virtually and reduce the number of physical prototypes required represented a significant opportunity to reduce expenditures.

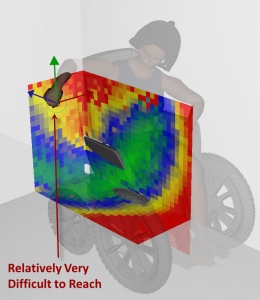

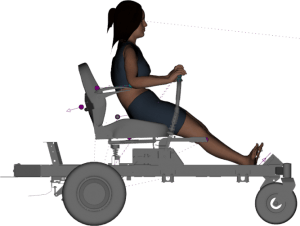

Our predictive human models quickly indicated that smaller women would have to sit much further forward on the seat to effectively operate the primary controls than had been anticipated by the design. After demonstrating our initial findings, the client revealed that many of the complaints were actually from smaller women who said they could not keep the lawnmowers running. Prior to our demonstration, the manufacturer had assumed this was due to operator error. After seeing our presentation, they remembered that the vehicle seat assembly included a kill switch designed to turn the engine off if sufficient pressure is not applied while the vehicle is moving.

Our predictive human models quickly indicated that smaller women would have to sit much further forward on the seat to effectively operate the primary controls than had been anticipated by the design. After demonstrating our initial findings, the client revealed that many of the complaints were actually from smaller women who said they could not keep the lawnmowers running. Prior to our demonstration, the manufacturer had assumed this was due to operator error. After seeing our presentation, they remembered that the vehicle seat assembly included a kill switch designed to turn the engine off if sufficient pressure is not applied while the vehicle is moving.

One of the world’s largest consumer goods manufacturers indicated that customers who have bad experiences with product bottles may never purchase those products again. As a result, the company created a department to evaluate new bottle designs through traditional means including physical prototypes and focus group testing.

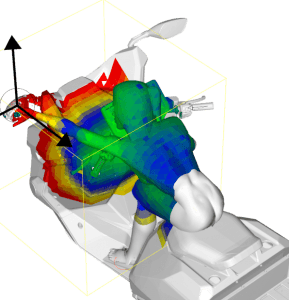

One of the world’s largest consumer goods manufacturers indicated that customers who have bad experiences with product bottles may never purchase those products again. As a result, the company created a department to evaluate new bottle designs through traditional means including physical prototypes and focus group testing. After receiving the CAD geometry for the new and old ultrasound wand designs, Santos® predictive models were used to simulate a variety of medical technician-in-the-loop use activities. Within two days, our evaluations indicated that, relative to the old design, use of the new design appeared to increase exposure to risk of injury.

After receiving the CAD geometry for the new and old ultrasound wand designs, Santos® predictive models were used to simulate a variety of medical technician-in-the-loop use activities. Within two days, our evaluations indicated that, relative to the old design, use of the new design appeared to increase exposure to risk of injury.