Blog Series: Failing to Optimize the Human-in-the-Loop at the Earliest Stages of Design is More Expensive than You Think – 2 of 3

Welcome to the second post in this blog series which continues with two additional examples on how traditional approaches to product design negatively affect your company’s bottom line and market share. The first post, which can be found here, provided examples from the Consumer Products and the Medical Device industries. This post focuses on examples from the Industrial Lawn Care and the Powersports & Small Utility Vehicles industries.

Example #3: Industrial Lawn Care

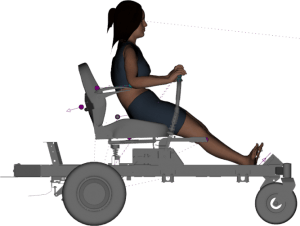

A manufacturer of industrial lawn care equipment had received enough complaints regarding the usability of one of its products to become concerned. As with most industries, poor customer feedback has a direct impact on market share so they needed to address this quickly. SantosHuman was contacted to help identify the operator-centric issues.

Our predictive human models quickly indicated that smaller women would have to sit much further forward on the seat to effectively operate the primary controls than had been anticipated by the design. After demonstrating our initial findings, the client revealed that many of the complaints were actually from smaller women who said they could not keep the lawnmowers running. Prior to our demonstration, the manufacturer had assumed this was due to operator error. After seeing our presentation, they remembered that the vehicle seat assembly included a kill switch designed to turn the engine off if sufficient pressure is not applied while the vehicle is moving.

Our predictive human models quickly indicated that smaller women would have to sit much further forward on the seat to effectively operate the primary controls than had been anticipated by the design. After demonstrating our initial findings, the client revealed that many of the complaints were actually from smaller women who said they could not keep the lawnmowers running. Prior to our demonstration, the manufacturer had assumed this was due to operator error. After seeing our presentation, they remembered that the vehicle seat assembly included a kill switch designed to turn the engine off if sufficient pressure is not applied while the vehicle is moving.

In this example, the product was already in production and receiving poor customer feedback. Focus groups could have evaluated fully functional physical prototypes prior to production to gain similar insight, but how would that have helped?

When evaluating human-in-the-loop issues for a mature design, there are basically two options available when a need for change is indicated that far downstream in the design process. You can go back and ask for the budget to redesign the product based on the insight gained. Or, you can go forward with the intention of leveraging that insight in some future iteration. Regardless of which of those options are chosen, we begin to see why traditional design processes make it almost impossible for product usability insights to be incorporated effectively. But, we’ll dive deeper into that with the third and final post in this series.

Example #4: Powersports & Small Utility Vehicles

Example #4: Powersports & Small Utility Vehicles

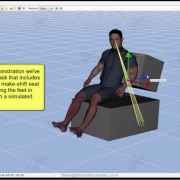

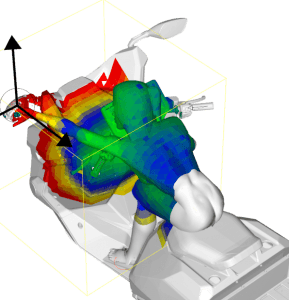

In this last example, a startup company outsourced two years’ worth of aesthetic and mechanical design towards the development of a new electric utility scooter. After all design efforts were complete, the company also outsourced the creation of a production-ready prototype to present to their investors. We were told that while the prototype scooter “looked fantastic”, they soon realized it was an “ergonomic mess” and SantosHuman was asked to help identify the issues. Over the course of a single weekend, our predictive human models provided a variety of operator-in-the-loop trade-off analyses that could be used to inform and support redesign efforts.

Again, while the ability to quickly and objectively evaluate mature product designs for human-centric issues has significant value, that is not the moral of the story. Rather, the examples presented in this and the previous post in this series are symptomatic of much larger problems which will be discussed in the final post on March 4th, 2019.

In the meantime, think back on the examples presented and imagine that these are your teams. Imagine the cost of developing an electric utility scooter over two years. Imagine the cost of creating a production-ready physical prototype of a vehicle like that. And just in case you’re not aware of how expensive physical prototypes can be to create, consider that there is a rumor that the first working iPhone cost $1.5M. With that in mind, imagine discovering that while your go-to-market product met the aesthetic and capability goals, it wasn’t fit for human use. Now imagine having to choose between entering a market where your first sale may be your last – or – asking your investors for additional funds for significant redesign efforts. Does this seem like the career-enhancing moment that was likely envisioned when the project began two years earlier? What would you have done differently? Why do you think that would have helped?

Our experience with many companies, over many years, indicates the scenarios presented in these first two posts are not only common, they are pervasive throughout most industries. Budget and deadline overruns, market rejection based on poor customer feedback, costly and time-consuming product redesigns, and amplified risk of injury liabilities are not the kinds of things you want to leave to chance. So, tune in on March 4th, 2019 for the final post in this series to find out why traditional design processes are at odds with truly human-centric design and to discover a solution.

Until then, let us know what you think. We’d love to hear from you.

– S