This month’s Q&A with Steve Beck, CEO of SantosHuman Inc., addresses the benefits of Santos® to your company.

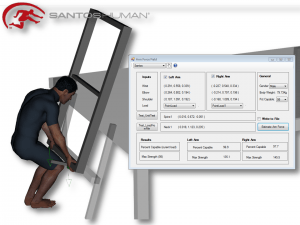

Q: What are the benefits of using Santos® technologies?

A: Let’s look at this question from 3 different perspectives, all in terms of reducing costs. We’ll start with the U.S. Government because, frankly, SHI wouldn’t exist without them. Then we’ll look at Private Industry and finally from the perspective of Safety.

U.S. Government

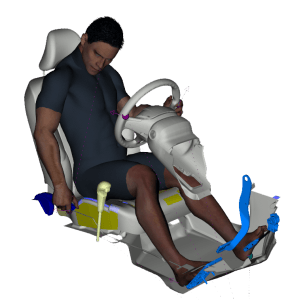

The original funding for what is now commonly referred to as Santos came from the U.S. Army Tank-Automotive & Armaments Command (TACOM) in 2003. TACOM program managers explained their motivation for this program in the following way. They told us that the next generation tank would take approximately 13 years to go from white paper to production. Historically, within those 13 years, 9 physical prototypes would be required. Each of those physical prototypes would cost approximately $1B (2003) and 90% of that cost (funded by US Taxpayers) would be committed as soon as the contract to build the prototype was awarded. They also said that one of the critical reasons for creating these physical prototypes was to make sure Warfighter-in-the-Loop issues are understood and addressed prior to production because getting those wrong would cost lives.

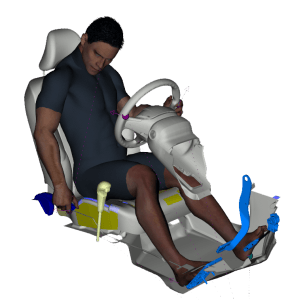

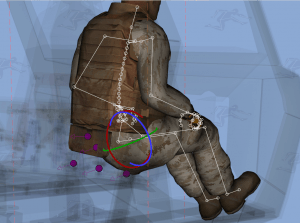

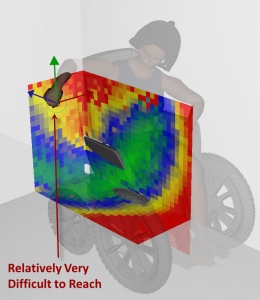

Their initial assumption had been that an existing commercial, off-the-shelf (COTS) digital human model (DHM) could be deployed early enough within design cycles to reduce the number of physical prototypes required. This would reduce the cost of, not just next generation tanks, but any new system and allow better designs to be brought into production sooner. However, upon completing a survey of the COTS DHM options available, they determined none of them could be used to achieve this goal. What they said they needed was a way to predict what the Warfighter would do and the program funding, therefore, was a catalyst for DHM research that could lead to capabilities more closely aligned with US DoD DHM requirements.

Their initial assumption had been that an existing commercial, off-the-shelf (COTS) digital human model (DHM) could be deployed early enough within design cycles to reduce the number of physical prototypes required. This would reduce the cost of, not just next generation tanks, but any new system and allow better designs to be brought into production sooner. However, upon completing a survey of the COTS DHM options available, they determined none of them could be used to achieve this goal. What they said they needed was a way to predict what the Warfighter would do and the program funding, therefore, was a catalyst for DHM research that could lead to capabilities more closely aligned with US DoD DHM requirements.

In the world of Defense Contracting, Santos represents a Warfighter-Centric alternative to the traditional Trial & Error approach to system design that can save billions in taxpayer expenditures.

Private Industry

Many years ago, I had asked our contacts at one of the world’s largest automobile manufacturers what Santos technologies meant to their industry. Based on data from over 100 years of designing and manufacturing automobiles, they said every new vehicle design historically comes with about 5000 problems. Any of those problems that can be addressed prior to production represents a savings of about $50,000. And in the year this conversation took place, they indicated 9 new vehicles would be going into production.

Those numbers suggest $2.25B worth of cost savings if 100% of the issues could be addressed prior to production. However, they also indicated that not all of those issues are human-centric. Paint, for example, might not cure correctly or hoses may not fit or door assembly mount points may be misaligned. While those are obviously not human-centric issues, they said anywhere between 10% and 20% of those 5000 issues are human-centric.

If you run those numbers and divide by 9 new vehicles, Santos represents savings of between $25M and $50M per new product for one company in a single year because Santos predictive models provide a unique ability to inform and support human-centric design decisions at the earliest stages of product development.

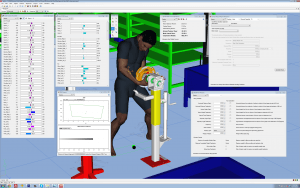

Safety

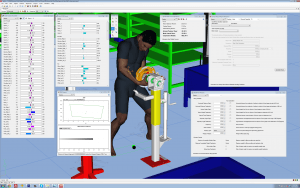

US companies spend between $50B and $70B per year on work-related injuries. In addition, our contacts within the U.S. DoD have said that the greatest source of lost days for Warfighters is due to equipment use. With that in mind, consider that an extensive study by two World-renowned ergonomists shows that commonly used tools to assess exposure to work-related risk of injury can be off by as much as 16 lbs. This means that even though your company may be assessing tasks for risk of injury, there’s a pretty good chance task risk is being under- or over-estimated.

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury.

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury.

Overestimating risk means expensively and needlessly redesigning tasks that could safely be accomplished as originally designed. Either way, these costs significantly affect the bottom line of just about every company in every industry. And this is why Santos technologies include the world’s most accurate and most extensively validated method of predicting exposure to risk of injury available today. Use this link if interested in finding out more.

Back to the original question. What are the benefits of using Santos? A better question might be, what does it cost to NOT use Santos?

Thanks for tuning in. You can learn more about other Santos capabilities here and, as always, let us know what you think. We’d love to hear from you.

– S

Their initial assumption had been that an existing commercial, off-the-shelf

Their initial assumption had been that an existing commercial, off-the-shelf

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury.

Underestimating risk means exposing your workers to increased risk of injury and this is critical for 2 reasons. Not only does it impact the lives of your employees, cost of injury calculators indicate that a single back injury with a $100K payout can have a ripple effect throughout a company requiring an additional $4.2M in sales to offset the cost of just that one injury. Designing for Humans Earlier in the Process. The Santos first-principles approach to predicting physical human behavior and performance allows human-in-the-loop criteria to be considered at the earliest stages of product development. This enables our defense and private industry clients to design for increased performance and increased customer satisfaction from the start resulting in

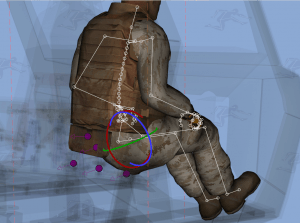

Designing for Humans Earlier in the Process. The Santos first-principles approach to predicting physical human behavior and performance allows human-in-the-loop criteria to be considered at the earliest stages of product development. This enables our defense and private industry clients to design for increased performance and increased customer satisfaction from the start resulting in